INNOVATIVE TEST SOLUTIONS FOR EV SECTOR

The rapid rise in demand for electric vehicles (EVs) in the automotive market has brought new technological challenges for manufacturers, especially in the area of testing. Seica has developed innovative solutions to address the issues involved in testing all EV components, a crucial step to ensure their safety and reliability.

Battery Testing

One of the main challenges is ensuring the quality and reliability of the electrical connections between battery cells, which are essential for the battery pack’s proper operation.

To meet the growing need for electrical testing of the bonds inside battery packs, Seica has introduced a new line of flying probe systems: Pilot BT, Pilot BTV, and Pilot H4BT.

The Pilot BT system can test the battery pack from the TOP side, performing precise parallel Kelvin tests on more than 32 cells at once, achieving a production rate of almost 4,800 cells per minute in its maximum configuration. It features a large testing area and uses the Bosch handling system to transport batteries.

For more complex battery packs requiring access from multiple sides, Seica has introduced the Pilot BTV (Vertical Battery Tester), a flying probe system that allows simultaneous and automatic access on three sides.

To cater to prototype labs or production lines with high product variety and medium volumes, the Pilot H4 BT has been developed. It has four independent axes for quick, parallel testing of 2 bonds at the same time, with a test area of 800 x 540 mm and a speed of over 600 tests per minute.

Seica received the prestigious 2024 Mexico Technology Award in the category of Flying Probe Testing for Electric Vehicles (EV) for its Pilot BTV system.

ACIR Testing

Another crucial aspect of battery testing is measuring the internal resistance (IR) of the cells. Uneven current distribution can cause dangerous temperature variations within the battery pack. Seica offers solutions for both direct current (DCIR) and alternating current (ACIR) resistance measurements, with tools like the Mini80 and Mini200, which can be integrated into automated systems or used for manual testing.

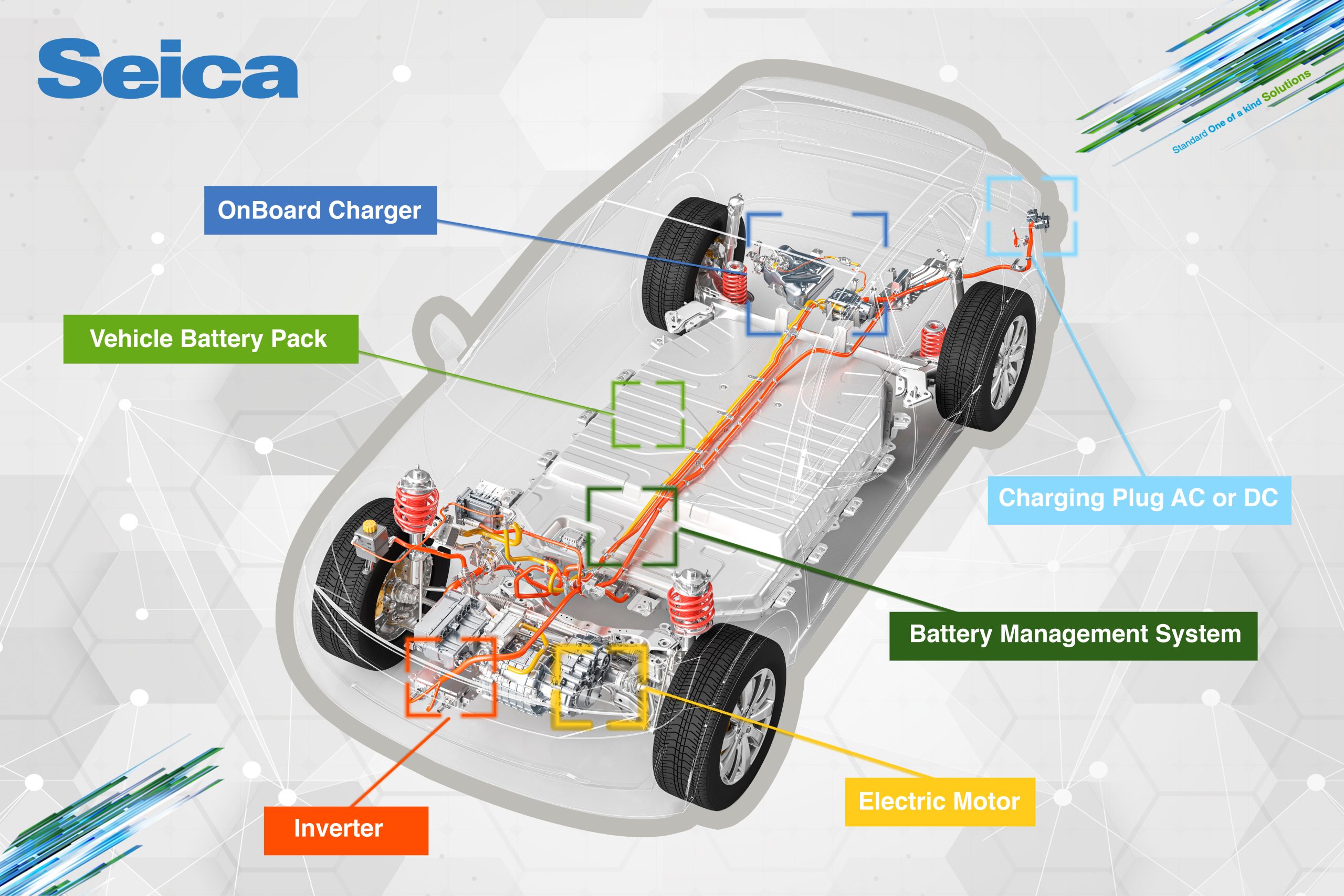

Battery Management System

The Battery Management System (BMS) is another key component, crucial for the performance, reliability, and lifespan of the battery. To ensure that each BMS meets its specifications, a full functional test is necessary, which involves simulating the real operating conditions the BMS will encounter. Seica has developed the Compact BMS Test System to carry out comprehensive functional tests, simulating scenarios such as cell balancing and temperature fluctuations, ensuring the system operates correctly under all conditions.

OBC and Inverter

The OnBoard Charger (OBC) module is an essential part of electric vehicles, responsible for recharging the battery pack when the vehicle is stationary. The inverter module serves a similar role, but in reverse, powering the electric motor.

To thoroughly test these two modules, Seica has developed two systems based on its Compact MULTI platform: Compact Multi-OBC and Compact Multi-Inverter.

Electric Motor

Testing the full functionality of an electric motor requires specific expertise and a purpose-built system. Seica offers the EMT EOL line, which comes in three variants (250/600/3000), allowing for the testing of a wide range of electric motors.

With nearly 40 years of expertise, Seica remains a trusted partner for EV manufacturers, delivering innovative and tailored testing solutions to keep pace with the ever-changing market. For more information: sales@seica.com