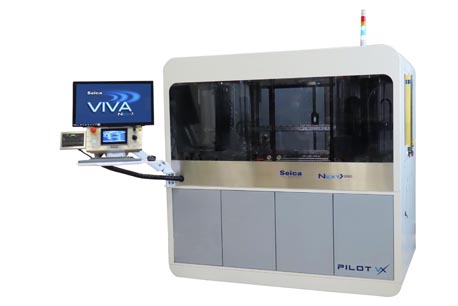

Pilot VX

Pilot VX is a flexible, configurable flying Probe test system with an unrivaled set of technologically advanced tools, able to provide the test solutions required by the huge diversity which characterize today’s electronics.

Seica has designed the Pilot VX to raise the bar of flying probe test performance, with cutting-edge solutions that address the fundamental concerns of electronic board manufacturers looking to optimize their investment.

Time is a cost: so a reduction of 50% in test time saves you a lot of money. This is thanks to new state-of-the-art mechanical performance and motion control system. The Pilot VX has 8 multi-functional test heads providing the capability to contact up to 60 points simultaneously. The system is equipped with innovative measurement hardware, a new microwave-based measurement technique, and optimized VIVA software management. This enables the parallelization of different types of tests and smart analysis capabilities. Together with algorithms based on the principles of artificial intelligence, the system can automatically optimize the test flow in run-time. The result is a dramatic reduction in test time without compromising on test stability or coverage.

Flexibility is key: that is why the Pilot VX allows you to make the most of your investment by meeting more of your current and future needs. Instead of investing in various systems to meet development production capabilities, one general-purpose system is enough. A large selection of test instruments means that the testing process can be tailored to the specific requirements of the product under test. Whether it be a simple bare board, a complex pcb with passive and active embedded components, a fully loaded double-side board, a flexible pcb, a very large or very small pcb, … All needs can be met with one system providing operations like flashing, electrical or optical LED tests, boundary scan, communication tests, connector integrity test, etc.

Traceability is a requirement: it gives you complete knowledge of the test process, allowing you to certify the quality of the product and to improve yields. This can be done through defect analysis to diagnose problems in the upstream manufacturing process. Going beyond the ability to store only the testing data, the Pilot VX can collect and store information regarding the mechanical pressure applied by the test probes. This is done for every point on the board, making it available for visual, graphical and statistical analysis. The result is you can truly certify gentle contact, no need to rely on strain gauges or statistical methods anymore.

High precision is a must: to meet the mechanical challenges of probing the extremely miniaturized pads of today’s components. As well as electrical precision to be ready for tomorrow’s testing needs and Seica’s innovative test approaches. With a positioning precision of +/- 10 μm, the Pilot VX is able to probe 50 μm pads, and measure values down to 25 fF capacitance or 200 μohm resistance. With a minimum laser spot of 200 μm, the integrated laser inspection tool can perform presence/absence checks of even 008004 SMDs.

Automation is a reality: it is omnipresent in today’s factories. This creates the need to manage not just a stand-alone system, but to integrate it mechanically and digitally with any other line element, from any manufacturer, old or new. Armed robots, horizontal or vertical lines, autonomous robots, pallets, etc. are all supported by the tester in a fluid, optimized, and intuitive manner.

The Seica Asset Manager (SAM) software suite is a configurable platform that can easily perform basic functions such as the connection of a test system to the factory MES. It also has the potential to supervise all of the assets in a robotized line according to the MQTT Broker IIOT standard. Which can then be monitored on a remote PC, tablet or mobile device via the customizable Seica Dashboard App.